What's New

Check back here regularly to find out what's going on at Regal Precision Engineers (Colne) Ltd.

May 2019

Charity Football Match raises £4136 for Pendleside Hospice.

Final Result: NR Engineering (2) – Regal Precision Engineers (3)

NR Engineering went head to head against Regal Precision Engineers in a charity football match on Sat 11th May 2019. They raised £4,136 for Pendleside Hospice !

The event was held at Colne Football Club and included bouncy castles, games, face painting, a ‘beat the goalie’ event, plus a very interesting performance by the Rock-It! team from the Helen Green Academy of Dance.

Many thanks to all those that supported the event, including Colne F.C. They not only allowed the use of their facilities, but also provided refreshments – all down to their volunteer staff

February 2019

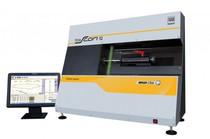

Regal are delighted to announce the arrival of a new Matsuura MX520 5-axis machining centre. This will add extra capacity to our 5 axis section.

2 x MX-520

2 x MX-330 with PC10 (10 pallet automation)

Travel: X 630 / Y 560 / Z510 / A -125 - +10 / C360

Spindle: 12000rpm

March 2018

April 2017

November 2016

October 2016

February 2016

Regal are delighted to announce the arrival of a new Matsuura MX520 5-axis machining centre. This investment is an indication of the improving fortunes of Regal plus adding more value and capacity to its customers. A long term goal is to explore robotic automation, more on that in the future. Exciting times.

Travel: X 630 / Y 560 / Z510 / A -125 - +10 / C360

Spindle: 12000rpm

January 2016

December 2015

May 2015

Congratulations to all involved over the last few months as we are proud to announce that Regal Precision Engineers Ltd have been granted AS9120 approval. With this approval now in place Regal Precision Engineers Ltd can supply all your product needs, From manufacture of product with AS9100 / ISO 9001 release to delivery of stocked items with AS9120 release (Mechanical, Electronic, Electrical, Electro Mechanical Components, Sealants, Coatings & Materials).

Please contact Richard Franklin for all your supply enquiries.

March 2015

Businesses have been throwing their weight behind an extra special raffle for an extra special little boy and his family. Organised by Matthew Eyre, the fund-raiser will take place outside Colne Market Hall from 9am

on Saturday. All money raised will be split between the family of Thomas Procter-Whitham (3), who is battling meningitis, and Ronald McDonald

House, where his relatives have been staying while he is at Alder Hey Children's Hospital. Tickets for the raffle, which will be drawn at 2-30pm on Saturday, are priced £1. More than 150 eggs

have been collected and have been combined in to more than 60 prizes.

We would like to thank Regal Precision employee Jackie Naylor and all involved for the fantastic effort they have put in to the worthwhile cause. Jackie managed to arrange for the collection of over

40 Easter eggs from Regal's employees and a £100 donation from Ray Kitchen. (Company Director).

March 2015

February 2015

After Months of working closely with Pneumatrol and RAPT Regal Precision Engineers Ltd have been granted approval to supply the French railway network with pneumatic door components.

November 2014

September 2014

Regal Precision have upgraded their 4 seats of GIBBSCAM CAD/CAM software package to include 3 seats wireframe VOLUMILL and 1 seat 3D Solid & wireframe VOLUMILL. VOLUMILL is the next generation, ultra high-performance toolpath technology that provides many new easy-to-use features and new powerful capabilities that increase productivity and performance. Thanks to all at TECH CADCAM.

July 2014

Regal were fortunate enough to be invited to participate in the Northwest Aerospace Alliance's ASCE II project. Aerospace Supply Chain Excellence II was a scheme to take businesses from learner to world class status in a number of categories.

Regal chose to concentrate on four areas: Process Control, Asset Management & Total Productive Maintenance, New Product Introduction plus Inspection.

Working to an agreed template, and with the patient guidance of our mentor Louise McLaren, Regal made good progress in developing the business and embedding the improvements.

The Steering Group which included representatives from AIRBUS, Rolls-Royce and BAE Systems were complimentary of Regal's efforts and supportive of our plans for the future.

Click here to see a short video describing some features of Regal's journey.

February 2014

With Regal Precision recent investment of Star machines and TESA scan non-contact measurement machine it was apparent that we need to improve on our part cleaning process. We have managed to secure investment with a Guyson Ltd Orbit 600 Rotary hot parts washer. Offering exceptional performance in a short cycle time.

October 2013

Further investment to Regal Precision sliding head deptartment we have purchased a Star SR-32JN (non-guide bush) along with the FMB Turbo 3-36 bar loading magazine. To increase capacity and reduce material expenditure.

June 2013

Regal Precision is proud to announce an investment furthering our non-contact measurement capabilities. With the purchase of a TESA Scan 52 Reflex we can offer high technological performance with an unmatched ease of use offering an exceptional price/quality relationship.

April 2013

Regal Precision would like to thank all at Star for the help and support provide with the installation of the new Star SR-32J sliding head machine along with the FMB Turbo 3-36 bar loading magazine. The machine provides Regal Precision with an even greater capability for high productivity. With the machines free overlap machining feature and sub-spindle driven tooling we are able to offer high turnover of product while maintaining high accuracy and quality.

January 2013

Regal have been working for sometime with VISUALFAIR software and have now invested in VISUALCPIP (Control plan and inspection plan) software. The software provides our customer base reassurance standardised controls are in place to provide delivery of a high quality product.